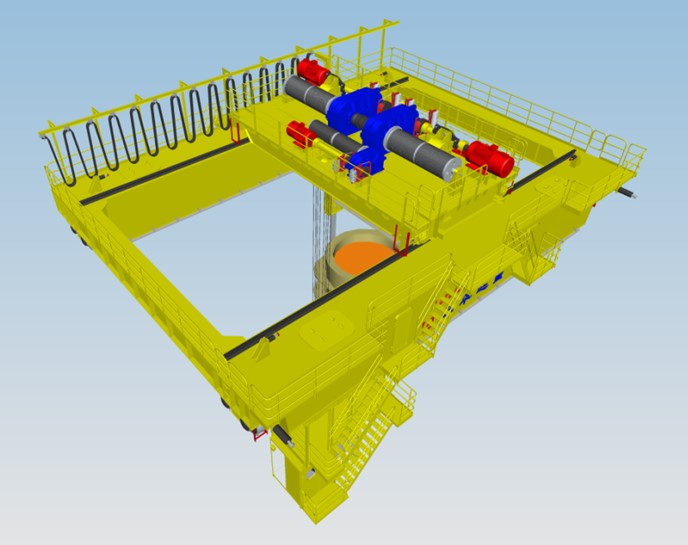

Rail Mounted Gantry Crane installation plan, according to the weight and technical parameter of crane largest part, it is planned to use the main lifting equipment is planned to use truck crane as the main lifting equipment, and lifting other parts assembly in the air.

Rail Mounted Gantry Crane installation plan, according to the weight and technical parameter of crane largest part, it is planned to use the main lifting equipment is planned to use truck crane as the main lifting equipment, and lifting other parts assembly in the air.

1. Rail Mounted Gantry Crane check after transport to the installation site.

2. Remove the adverse construction debris of the installation site, and set up obvious signs around the construction site.

3. Select the installation site, arrange the truck crane position, Rail Mounted Gantry Crane beams and legs, all parts put in place.

4. Rail Mounted Gantry Crane wheel sets and legs hoisting and installation.

Gantry crane's supporting legs are inclined. Its hoisting state is also inclined, compared to vertical lifting, its hook and precise alignment of large difficulty. Truck crane can choose rotation method and sliding method as ideal lift.

5. Rail Mounted Gantry Crane Main Girder Erection

1). Field measurement according to the actual situation; develop the truck crane stand position according to the working radius of the truck crane.

2). Inspection all the machinery and equipment in use, comprehensive inspect layout, connection and so on, main beam erection can be carried out after confirmed that no mistake.

3). Main beam to lift from the ground 100-200mm and static stay in the air 5-8 minutes; after check all the machines and equipment to confirm safety and reliability, the main beam can be slow to lift.

4). The truck crane must be commanded by one person, and the others to work together. No matter in any lifting height, main girder must be in balance at both ends.

5). Truck crane lift the main girder and saddle respectively on two main girder flange, bolts fastening connection.

6). Use instrument to check and measure Rail Mounted Gantry Crane installation accuracy; if there are unqualified items, it need appropriate adjustments, until satisfy the appropriate standards.

7). Remove the support leg firmware (cable wind rope or rigid support)

6. Rail Mounted Gantry Crane trolley winch erection

1). Select truck crane working position: according to trolley installation location requirements, determine truck crane suitable working position, to smoothly complete hoisting operation of the trolley components.

2). Remove the trolley rain cover, estimate trolley component weight and position, to prevent improper hanging and serious eccentric load.

3). Lift trolley 100-200mm from the support, observe whether the trolley plane in level state, and then check the equipment and fastened, confirm it firm and safe, so is ready to continue lifting.

4). Lift the trolley to a certain height, start the truck crane slewing mechanism, then lift trolley above the main girder, almost alignment of trolley tracks, then slow down, and then at the trolley track, trolley positioning in the trolley truck.

7. Rail Mounted Gantry Crane Driver’s Cabin Install

Driver's cabin mounting frame is welded to the inside of the rigid leg bottom of the main beam, move driver's cabin to the design installation position after main beam is lifted to a certain height.

8. Rail Mounted Gantry Crane ancillary facilities installation

Set position according to the drawing, install and check the installation quality of the control system, security alarm device communication facilities, maintenance platform, ladders, railings and so on.

9. Rail Mounted Gantry Crane Electrical equipment installation

Check the electrical control system circuit and components install according to the design drawing.

10. Fitter, electrician and inspector cooperate to adjust the Rail Mounted Gantry Crane each part, and then commissioning.

Rail Mounted Gantry Crane Installation Plan

Electric Wire Rope Hoist

We are electric wire rope hoist

Rubber Tyred Gantry Crane

Rubber Tyred Gantry Cranewith d

Rail Mounted Gantry Crane

Rail Mounted Gantry Crane Video

Dredge Crane Manufacturer

Dredge Crane and floating dock

Overhead Bridge Crane Man

Overhead Bridge Crane is one ki

Single Girder Crane Video

Single Girder Crane Video, Sing

Overhead Bridge Crane Spe

Overhead Bridge CraneSpecificat

Casting Crane Manufacture

Casting Crane include Single Gi

YGCRANE Gear Reducer Lead

Recently, Crane Manufacturers Y

Crane Manufacturers YGCRA

On April 24th ,2017, president

50 Ton Double Girder Gant

Recently, our new Double Girder

Double Girder EOT Cranes

Recently, with exporting contai

Bridge Crane with Hook

This type bridge crane with sup

Progress on Electric Wire

Recently, Crane Manufacturers W

RTG Crane Manufacturers Y

RTG Crane Pre-install and Test

RMG Crane Manufacturers Y

RMG Crane re-install and Test i

Crane and Girder Enquiry

Pls check the attached files, i

Gantry Crane Manufacturer

40 ton rail mounted container g

Port Crane Manufacturers

Rubber tyred container gantry c

Rail Mounted Gantry Crane

400m lifting height gantry cran

Social Counter

Directory

Contact Us

- Industry Park, Changyuan, Henan, P.R.C

- (0086) 15836006986

- sales@ygcrane.com