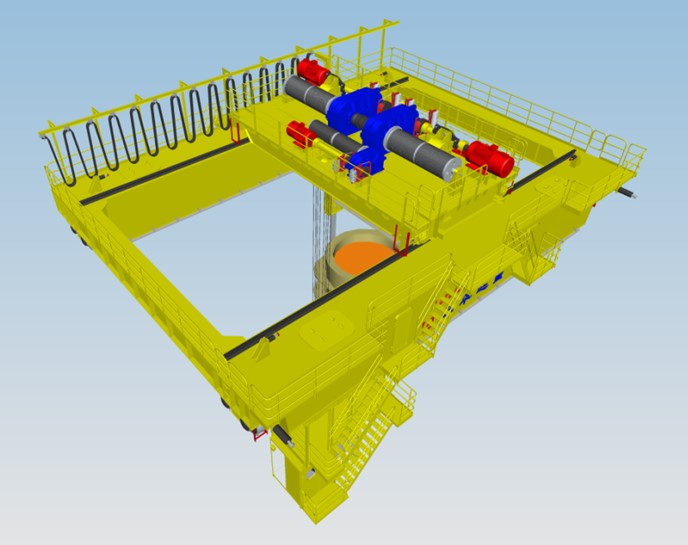

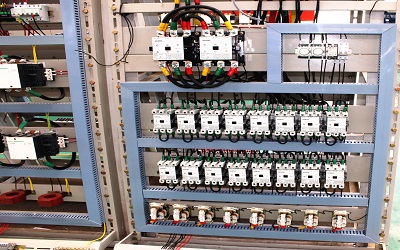

Crane System - Electric Control System control the operation of the crane.

Crane System - Electric Control System control the operation of the crane.

Crane steel structure is responsible for supporting load; crane movement starting, operation, reversing and stop by electrical or hydraulic control system to complete, to crane operation can steady, accurate, safe and reliable is inseparable from the effective electrical transmission, control and protection.

Crane electric system transmission

The requirements of the crane to the electric drive are: speed regulation, smooth or fast braking, deviation correction, synchronization and maintenance, inter agency coordination, lifting and locking, etc.. Which is often used as an important requirement. Crane speed performance is poor, when need accurate stopping, the driver can only take "car" the manipulation method, if a lot of times of "car", which not only increases the labor intensity of the driver, and due to electrical access times and electric motor starting times increase, and make the electrical appliances, motor working life is greatly reduced, increased accidents, maintenance increases. Some cranes require a higher accuracy, and must be implemented in order to meet the requirements of the stop. Some cranes to use program control, numerical control, remote control, the application of these technologies, often have to achieve the speed requirements, it is possible. As the majority of crane speed need to be carried out in the running process, and the number of changes is more, so the mechanical transmission is generally not Tai Heshi, most of the need to use electrical speed.

Electric speed regulation is divided into two categories: DC speed control and AC speed regulation.

DC speed control has the following three programs:

The fixed DC voltage power supply series motor, series resistance and change the connection of the DC speed;

DC generator of controlled voltage supply -- DC speed regulation of electric motor;

Thyristor power supply with controllable voltage supply -- DC speed regulation of DC motor system.

DC speed regulation has the advantages of high overload capacity, large speed ratio, good braking performance, suitable for frequent braking, low accident rate and so on. The disadvantage is that the system structure is complex, the price is expensive, needs the DC power supply and so on.

AC speed regulation is divided into three categories: frequency, variable polarity, variable slip.

Variable frequency speed control technology has been widely applied to the crane's stepless speed regulation operation, the main body of the electronic voltage transformer frequency conversion speed control system - frequency converter has a series of products available.

Pole changing control at present, it is mainly used in double hoist crane of squirrel cage type winding pole changing motor on the motor pole pair number to realize the speed change.

Variable slip speed is more, such as the change of winding asynchronous motor rotor series resistance method, SCR pulse speed regulation method.

In addition to the speed and double electric motor, the hydraulic push speed regulator and dynamic braking speed, rotor pulse speed regulation, cochlear flow speed brake, stator variable voltage and speed and so on.

Crane System - Electric Control System control the operation of the crane.

Crane System - Electric Control System control the operation of the crane. Crane System - Electric Control System control the operation of the crane.

Crane System - Electric Control System control the operation of the crane.